{"product":{"productId":"agid.16824","price":35.76,"name":"SHRINK DISC, D=48 D1=80, FORM:A STEEL"},"currency":"GBP"}

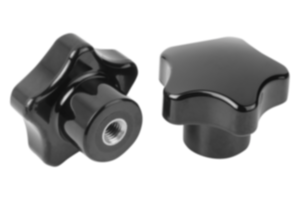

Shrink disc

steel

- To connect a hollow shaft to a shaft

- Suitable for static, dynamic and shock loads

- For very high torques

- No shift of axial shaft/hub during assembly

- Self-centring

Sales unit

£35.76

plus sales tax

Registered customers are offered live availability of the item after logging in to the website. Please log in or register to see the live availability or request a quotation.

Added to your shopping cart

Item

Shrink disc

Form

A

Main

material

steel

D1=Outside diameter

80

D=internal diameter

48

B

30

DW

36/38/40

L

26

L1

22

L2

11

Max. axial force F kN

with

tightening torque MS

65/72/78

Max. torque M Nm

with

tightening torque MS

900/1050/1200

No. of

screws

7 x M6

RoHS

true

Surface pressure

on hub P

N/mm²

260

Tightening torque

MS

Nm

12

Description

Material

Steel.

Version

Bright.

Note

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedge-formed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads.

- for extremely high torques

- no axial shaft/hub offset when assembling

- self-centring

The version 23380-01-4072 has high tensile ISO 4762 screws.

- for extremely high torques

- no axial shaft/hub offset when assembling

- self-centring

The version 23380-01-4072 has high tensile ISO 4762 screws.

Assembly

Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS.

1st increment approx. 33% MS

2nd increment approx. 66% MS

3rd increment 100% MS

Dismantling: Gradually loosen all screws one after the other but do not fully remove from the thread. The shrinking disc usually loosens itself.

1st increment approx. 33% MS

2nd increment approx. 66% MS

3rd increment 100% MS

Dismantling: Gradually loosen all screws one after the other but do not fully remove from the thread. The shrinking disc usually loosens itself.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.