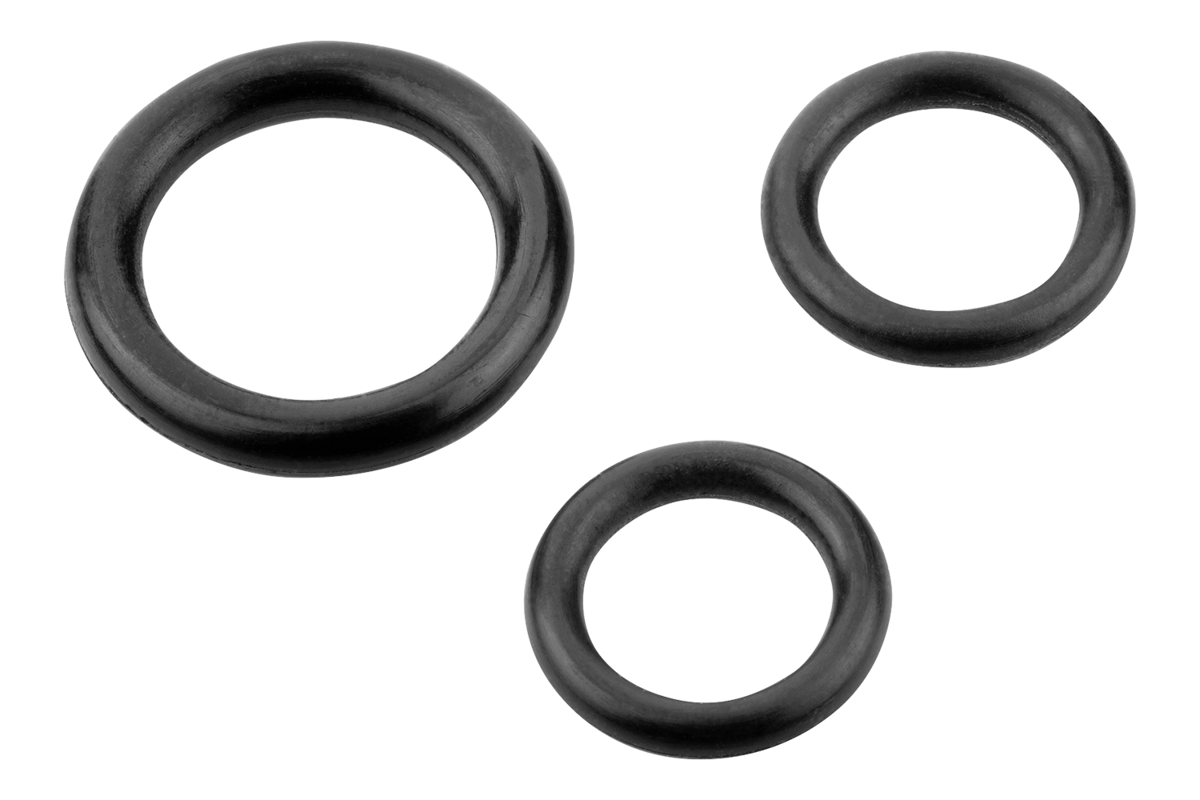

Material

Elastomer NBR.

Version

Shore ~70, black.

Show more

Show less

Description

Material

Elastomer NBR.

Version

Shore ~70, black.

Note

O-rings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. O-rings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the cross-section. During operation, the median pressure increases the deformation of the O-ring and so increases the sealing effectiveness. For best sealing effectiveness, the O-ring should have the largest possible cross-section.

During installation the correct groove size, compaction, elongation/compression should be ensured.

By static use the compaction should be 15 - 30% of the cross-section. By dynamic use it should be 10 - 18% (hydraulic), 4 - 12% (pneumatic).

With regard to the ID, when installed the O-ring should be

stretched max 6%

compressed max 3%

The material NBR has a high wear resistance and is resistant to mineral oil based lubricating oils and grease, hydraulic oils (H, H-L, H-LP), high-flashpoint pressure fluids (HFA, HFB, HFC), aliphatic hydrocarbons, silicon oil and grease, water up to ca. 80° C

During installation the correct groove size, compaction, elongation/compression should be ensured.

By static use the compaction should be 15 - 30% of the cross-section. By dynamic use it should be 10 - 18% (hydraulic), 4 - 12% (pneumatic).

With regard to the ID, when installed the O-ring should be

stretched max 6%

compressed max 3%

The material NBR has a high wear resistance and is resistant to mineral oil based lubricating oils and grease, hydraulic oils (H, H-L, H-LP), high-flashpoint pressure fluids (HFA, HFB, HFC), aliphatic hydrocarbons, silicon oil and grease, water up to ca. 80° C

Temperature range

-30 °C to +100 °C

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.