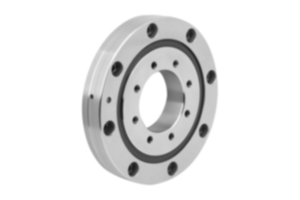

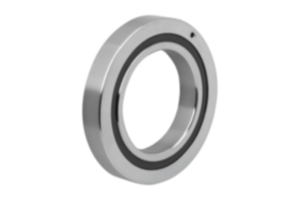

Axial Angular Contact Ball Bearing

double-row

steel

ground

- Support of high radial and axial loads

- High axial load rating due to the 60° pressure angle

- Suitable for high speeds

Sales unit

£216.22

plus sales tax

Registered customers are offered live availability of the item after logging in to the website. Please log in or register to see the live availability or request a quotation.

Added to your shopping cart

Designation

Axial Angular Contact Ball Bearing

Form

C

Version 1

double-row

Version 2

with flange

Body material

steel

Component material

nitrile rubber

Body surface finish

ground

B=Width

28 -0,25

D1=Outside diameter

75-0,01

D=Internal diameter

25-0,005

KZZ.=Abbreviation

2575-2RS

T1=Dynamic load ratings N

27500

T2=Static load ratings N

55000

U=Speed limit rpm

2600

Axial rigidity n/µm

750

Axial runout µm

2,0

B1

3

B2

19

Bearing friction torque Nm

0,40

Bore deviation µm

0-5

D2

40,5

D3

49

D4

6,6

D5

58

Form definition

with 7 holes

M

M06

Moment of inertia KGxcm²

0,486

Outside diameter deviation µm

0-10

R

0,3

R1

0,6

Radial bearing clearance

pre-tensioned

Tightening torque prec. locknu

25

Tilt rigidity Nm/mrad

200

Width deviation µm

0-250

α

60°

β

45°

Description

Material

Steel housing.

Nitrile rubber seal.

Nitrile rubber seal.

Version

Ground edges.

Technical Data

All bearings are supplied ready for mounting with lubricating grease type KE2P-35 acc. to DIN 51825.

Housing and shaft tolerances correspond to roundness tolerance class IT2 and perpendicularity tolerance class IT4.

Housing and shaft tolerances correspond to roundness tolerance class IT2 and perpendicularity tolerance class IT4.

Application

For thread drive bearing.

Temperature range

-30 °C to +120 °C.

Assembly

Precision slotted nuts must be used for mounting the threaded spindles.

To compensate for any material settling during assembly, tighten the slotted nuts using 2x tightening torque, loosen slightly and then tighten using the prescribed tightening torque.

Tighten fastening screws crosswise up to max. 70% of the yield point.

To compensate for any material settling during assembly, tighten the slotted nuts using 2x tightening torque, loosen slightly and then tighten using the prescribed tightening torque.

Tighten fastening screws crosswise up to max. 70% of the yield point.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.