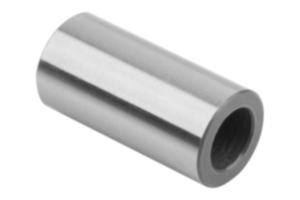

{"product":{"productId":"agid.16519","price":0.56,"name":"PLAIN BEARING CYLINDRICAL D=15, D1=17,L=12, STEEL, COMP:PTFE"},"currency":"GBP"}

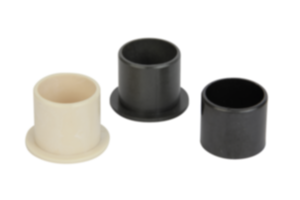

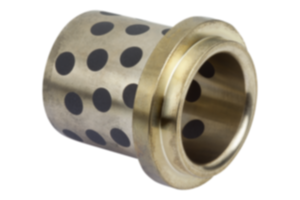

Plain bearing

cylindrical

steel

- Suitable for rotary and oscillating movements

- Maintenance-free

- Very low wear and coefficient of friction

- No stick-slip effect

- High chemical resistance

Sales unit

£0.56

plus sales tax

Registered customers are offered live availability of the item after logging in to the website. Please log in or register to see the live availability or request a quotation.

Added to your shopping cart

Item

Plain bearing

Version 1

cylindrical

Main

material

steel

Component

material

PTFE

D

15

D1

17

L

12

RoHS

true

Description

Material

Base material, steel.

Intermediate layer sintered bronze.

Bearing surface PTFE.

Intermediate layer sintered bronze.

Bearing surface PTFE.

Version

Steel tin-plated.

Note

Maintenance-free rolled composite steel plain bearings particularly suitable for dry running. Also highly suitable for lubricated applications (oil lubrication). Very low wear and friction, no stick-slip effect. Suitable for rotary and oscillating movements, high chemical resistance, low water absorption.

Technical Data

Static load: max. 250 N/mm²

Dynamic load: max. 140 N/mm²

Friction coefficient, dry: 0.03 to 0.20

Sliding speed, dry: max. 2 m/s

Sliding speed, oil lubricated: max. 5 m/s

Thermal conductivity: 42 W(m*K)-1

Thermal expansion coefficient: 11*10-6 K-1

Temperature range: -195°C to +280°C

Dynamic load: max. 140 N/mm²

Friction coefficient, dry: 0.03 to 0.20

Sliding speed, dry: max. 2 m/s

Sliding speed, oil lubricated: max. 5 m/s

Thermal conductivity: 42 W(m*K)-1

Thermal expansion coefficient: 11*10-6 K-1

Temperature range: -195°C to +280°C

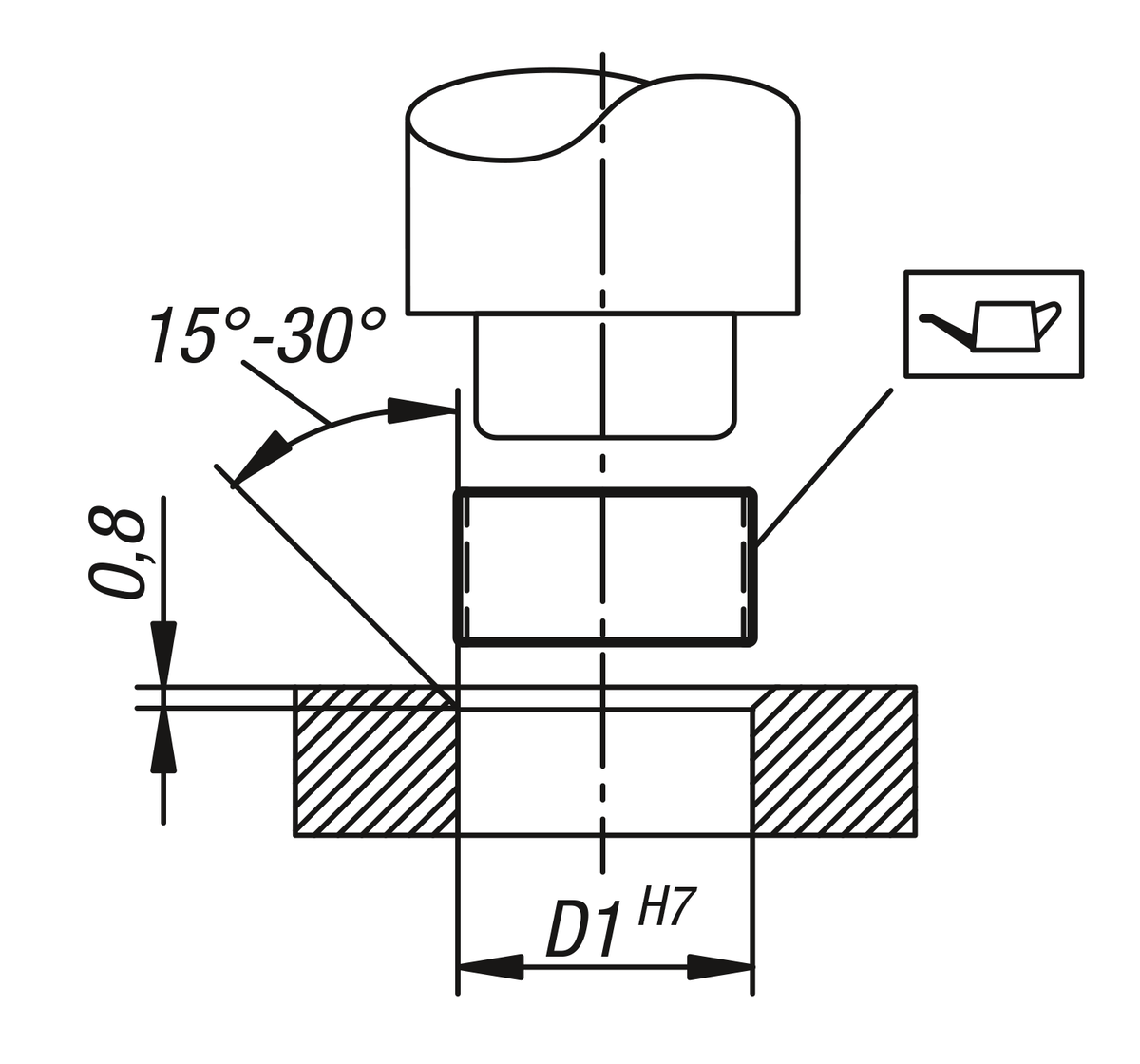

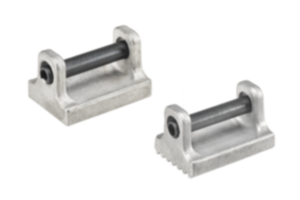

Assembly

The use of a suitable press mandrel is recommended to avoid damaging the bearing surface. The butt joint must be opposite the load zone. The bearing has an interference fit after installation. Gluing is possible but not required.

Tolerances

Housing:

Recommended tolerance H7.

Surface finish Ra 0.8 to 1.6.

Chamfer (press-in side 0.8 to 1.2 x 15°).

Shaft:

Recommended tolerance h8 to f7. For applications at a low speed and small loads drawn shafts with h9 can also be used.

Shaft surface Ra 0.4 to 0.8 (preferably ground shafts) for drawn shafts Ra 1.6 to 3.2.

Recommended tolerance H7.

Surface finish Ra 0.8 to 1.6.

Chamfer (press-in side 0.8 to 1.2 x 15°).

Shaft:

Recommended tolerance h8 to f7. For applications at a low speed and small loads drawn shafts with h9 can also be used.

Shaft surface Ra 0.4 to 0.8 (preferably ground shafts) for drawn shafts Ra 1.6 to 3.2.

Drawing reference

1) Butt joint

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.