{"product":{"productId":"agid.16820","price":40.23,"name":"KEYLESS LOCKING COUPLING, D=80 D1=120,FORM:F STEEL"},"currency":"GBP"}

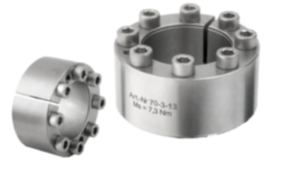

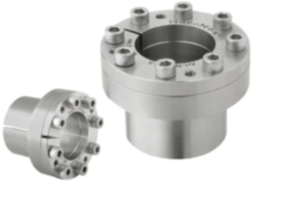

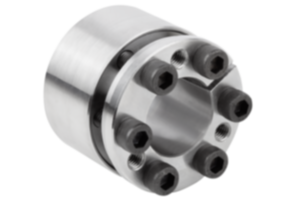

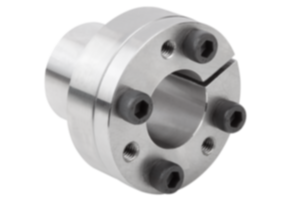

Keyless Locking Coupling

steel

- For medium to high torques

- No axial shift

- For shaft diameter from 19 to 85 mm

- Self-centring

Sales unit

£40.23

plus sales tax

Registered customers are offered live availability of the item after logging in to the website. Please log in or register to see the live availability or request a quotation.

Added to your shopping cart

Item

Keyless Locking Coupling

Form

F

Main

material

steel

D1=Outside diameter

120

D=internal diameter

80

B

50

D2

129

L1

24

L2

32

L3

40

Max. axial force F kN

with

tightening torque MS

130

Max. torque M Nm

with

tightening torque MS

5490

No. of

screws

8 x M10

Surface pressure

on hub P

N/mm²

120

Surface pressure

on shaft P

N/mm²

185

Tightening torque

MS

Nm

83

Description

Material

Steel.

Version

Bright.

Note

Keyless locking coupling with short axial width.

- for shaft diameters from 19 to 85 mm

- for medium to high torques

- no axial offset when mounting

- self-centring

- for shaft diameters from 19 to 85 mm

- for medium to high torques

- no axial offset when mounting

- self-centring

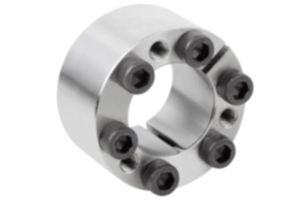

Assembly

Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque.

Dismantling: Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens.

Dismantling: Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens.

Tolerances

Shaft:

Recommended tolerance h8.

Surface quality Rz ≤ 16 µm.

Hub:

Recommended tolerance H8.

Surface quality Rz ≤ 16 µm.

Recommended tolerance h8.

Surface quality Rz ≤ 16 µm.

Hub:

Recommended tolerance H8.

Surface quality Rz ≤ 16 µm.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.