norelem measures – 31000

The product group 31000 from norelem consists of three categories:

- Inspection tables, instrument holders

- Gauge stands

- Accessories for gauge stands

Inspection tables, instrument holders

An inspection table is a versatile tool that is used in various areas of inspection and precision measurements. An inspection table is a flat, stable surface that has been specially developed to carry out quality tests and precise inspections of workpieces.

The inspection table usually consists of a large, flat worktop made of high-quality material such as granite. The surface is carefully machined and polished to ensure the smoothest and most accurate measuring surface possible. The size of the inspection table varies depending on the area of application and the parts to be measured. The norelem range includes six different inspection table sizes.

When carrying out measurements, the parts to be analysed are placed on the inspection table and positioned there. The precise level of the table provides a stable basis for taking accurate measurements.

There are different types of measurement such as length measurement, height measurement or differential measurement. The inspection table makes it possible to precisely check lengths, angles, parallelism, flatness and other dimensions of components. It is frequently used in manufacturing, quality assurance, construction and other technical areas where accuracy and precision are of great importance.

By using a inspection table, errors during measurement can be minimised and the quality of the parts produced can be improved. It also allows measurements to be compared across different points in time as the inspection table provides a standardised basis for measurement.

An inspection block is suitable for measuring small objects. A special feature is the fine adjustment function. Fine adjustment of a further two millimetres is possible. The inspection block can therefore be used for particularly precise work.

norelem offers the following product spectrum:

- Grey cast iron inspection table

- Support cylinder for workpieces with collar

- Inspection block with column

Dial gauge stands

Dial gauge stand are fixtures that are used to attach measuring instruments. They are used to hold the instruments in a stable and precise position in order to carry out accurate measurements. The stands are available in different versions to meet the requirements of different measuring applications.

An articulated arm stand is a flexible stand that consists of several joints. It makes it easy to adjust the position of the metrology instrument in different directions. The joints can be loosened or tightened to lock the stand and maintain its position. Articulated arm stands are well suited for applications where flexibility and adjustable positioning are required, for example in microscopy or precision mechanical work. The articulated arm stand from norelem consists of four parts and is clamped in the centre by a clamping head.

A magnetic gauge stand is a dial gauge stand that is equipped with a magnetic base. The magnetic base enables quick and easy fastening to metallic surfaces without the need for additional fasteners. This stand is particularly useful when metrology instruments need to be fastened to machines or other magnetic surfaces. It provides a stable mount and enables precise measurements in a specific position.

A magnetic stand, on the other hand, is simply a stand. It is designed for use with magnetic metrology instruments. The magnetic stand has a magnetic holder into which the metrology instrument is inserted. The magnet ensures a firm connection between the stand and the instrument.

The difference between an articulated arm stand, a magnetic gauge stand and a magnetic stand lies in their design and use. While the articulated arm stand offers flexibility and adjustable positioning, the magnetic gauge stand and the magnetic stand enable quick and easy fastening to magnetic surfaces. The latter are specially designed for use with magnetic metrology instruments and provide a stable mount for precise measurements.

Accessories for dial gauge stands

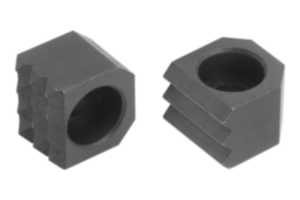

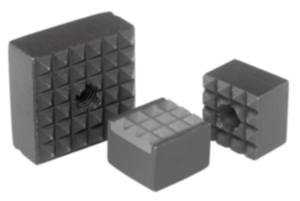

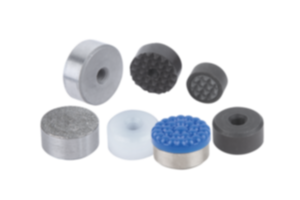

Accessories for dial gauge stands include a variety of components that extend the function and versatility of the stands. Accessories such as swivel joints, dial gauge holders and clamping joints considerably extend the application possibilities for the stands. With these additional components, measuring instruments can be flexibly positioned, securely fastened and precisely aligned. This improves the accuracy and efficiency of measurements and supports a wide range of applications in areas such as manufacturing, quality assurance and research.

At norelem, the accessories for dial gauge stands are reflected in the following products:

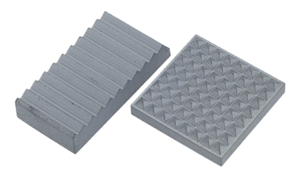

- Different joints

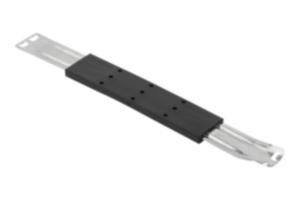

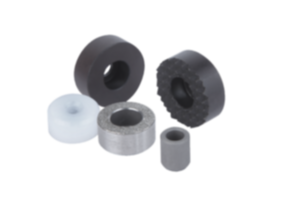

- Dial gauge holders and dial gauge holders with fine adjustment

- Clamping joints