Indexing plungers from norelem – Precision and reliability for your applications

Product selection at norelem

Diverse application uses for indexing plungers

Why you should choose indexing plungers from norelem

Indexing plungers from norelem – Precision and reliability for your applications

An indexing plunger is a standard indexing unit. It can be used to index and lock moving machine elements in specific positions. The pin - also be referred to as an indexing pin - and can be engaged and disengaged manually or automatically.

Indexing plungers are often used in machines, tools, fixtures or hinges. There they prevent the unwanted movement of components.

The classic plunger has a pull knob or a pull ring. To ensure a stable coupling, the pin is inserted into a hole or a recess in another part.

When the knob or ring is pulled up, the indexing pin is retracted from the opposite part. This enables the connections to be fixated or released quickly and easily.

The main purpose of an indexing plunger is to join two or more parts together so that they remain in a fixed position. This prevents unwanted movements or displacements.

Many indexing plungers are designed so that they can be easily unlocked. This makes it easier to release the connection and enables the parts to be moved. Some indexing plungers are fitted with a spring mechanism. This automatically pulls the pin back into the lock position as soon as it is released.

Product selection at norelem

The range contains 40 different indexing plungers. The individual indexing plungers are available with the most common pin lengths (from 24 mm to 134 mm). The range also includes pins with different diameters (3 mm to 25 mm).

The material of the main body can also be selected via the filter option. These can be made from free-cutting steel, stainless steel, carbon steel or thermoplastic. Various factors play a role in selecting the correct material for indexing plungers. These can include strength, corrosion resistance and weight. Free-cutting steel, stainless steel, carbon steel and thermoplastic each offer specific advantages that make them particularly suitable for different applications.

Free-cutting steel is inexpensive to machine and offers excellent surface quality. In comparison, stainless steel stands out due to its high corrosion resistance. Stainless steel is ideal for applications in damp or aggressive environments, such as in the foodstuff industry or outdoors. It is resistant to corrosion and chemical influences. Stainless steel is also hygienic and easy to clean, making it indispensable in medical technology.

Carbon steel offers exceptionally high strength, making it ideal for applications that are subject to high loads. This steel is also available with a variety of alloys so that it can be adapted to specific requirements such as impact strength. It is often more cost-effective than stainless steel, especially in environments where corrosion resistance is not the top priority.

Thermoplastic excels due to its lightness and corrosion resistance. Thermoplastic is significantly lighter compared to metals and still offers high resistance to moisture and many chemicals. Its flexibility gives it increased impact resistance, although it does not have the same strength as metal.

There are different types of indexing plungers, depending on the application. These can be operated manually or automatically. Various shape designations of the indexing plungers summarise their small differences. The norelem range includes models:

- with thread lock

- with extended indexing pin

- short versions

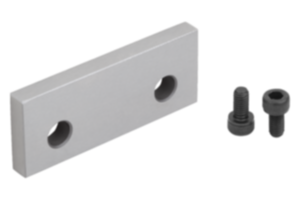

- for thin wall parts

- as an ECO version

- with lock

- with rotation lock and lead-in chamfer

- with locked mark

The pneumatic indexing plungers sets new standards in automation. They are operated by applying compressed air. The pin is reset by interrupting the air supply. Pneumatic indexing plungers are used in e.g. synchronised production systems or assembly equipment as well as in safety-related applications that do not permit manual actuation.

P

For certain areas where the locking pin should not exceed a certain depth, there are plungers with thread lock. The thread lock enables the installation depth to be precisely matched to the existing components, so no locknut is required.

In difficult to access installation spaces where operation is restricted or remote operation is required for ergonomic and safety reasons, the indexing plungers with remote control are the optimum solution. A Bowden cable is used to connect the plunger to the operating site. The combination of indexing plunger and actuating element forms a complete system which can be used for many types of application. As an alternative to the actuating element, the enclosed screw nipple (Ø5 x 7 mm) can be used to integrate an individual actuating element into the system.

Diverse application uses for indexing plungers

Indexing plungers consist -simply put - of a sleeve with a pin inside. When the grip is pulled up, the pin retracts into the sleeve. The position of the moving part can then be changed. As soon as the desired position is reached, the grip is released, the pin advances and reliably fixates the position of the moving part.

These pins are particularly robust and can withstand even the strongest lateral forces, ensuring a secure lock. Only the manual intervention of the user changes the locking position, whereby the position is securely maintained.

Additional advantages of the indexing plungers are:

Wide range of grip types: The indexing plungers from norelem are available with diverse grip types, including mushroom grips, T-grips, star grips, rings, spherical knobs and more. This diversity enables flexible adaption to a wide range of application situations.

Strong retaining forces: Our indexing plungers offer a strong retaining force, which ensures secure fixation of moving parts. This ensures stability and safety for the application, even under extreme conditions.

Simple integration and operation: The norelem indexing plungers are easy to integrate and offer user-friendly operation, that enables rapid locking and unlocking. This reduces setup times and increases production processes.

The robust construction and the availability of different models make our indexing plungers suitable for a wide range of applications in various industries, from machine construction to automation.

Indexing plungers can be used for:

- Securing swivelling and rotating devices

- Stop positioning

- Height adjustment

- Quickly disconnecting components

Why you should choose indexing plungers from norelem

When it comes to choosing indexing plungers, norelem products offer numerous convincing advantages that make them the first choice for users in a wide range of industries. Indexing plungers from norelem are characterised by high precision, reliability and exceptional resilience. These plungers can withstand even the strongest lateral forces.

Thanks to robust materials such as carbon steel and stainless steel, the indexing plungers are especially resistant to wear and corrosion. During the quality inspection, special attention is paid to exact tracking and perfect engagement in the end position. This quality in the plungers ensures smooth functionality in practice.

Another reason to opt for indexing plungers from norelem is the diversity in the range. With an extensive assortment of different product types, designs and pin diameters, at norelem you will always find precisely the correct solution for your specific requirements. Using the filter function, you can easily choose between different requirements to find the perfect solution for your specific needs.

If you value reliability, flexibility and durability, indexing plungers from norelem are the ideal choice for your projects.