{"product":{"productId":"agid.2262","price":40.2,"name":"Self-aligning pads, adjustable with O-ring and hexagon socket, Form O, stainless steel ball with diamond impregnated face"},"currency":"GBP"}

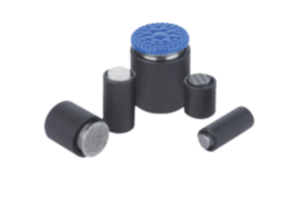

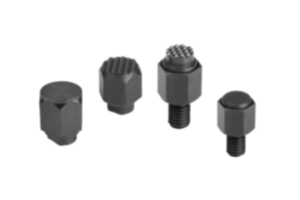

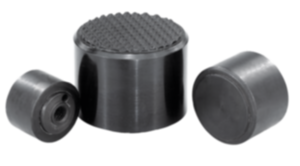

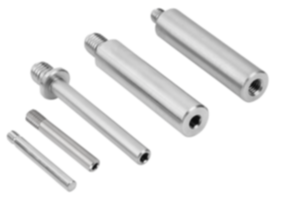

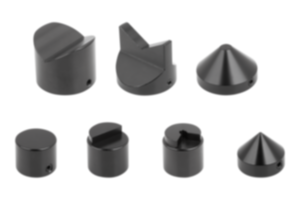

- Serve as supports, stops and thrust pads

- Application sectors: machine and fixture construction, assembly

- Form O: diamond surfaces offer excellent wear resistance

- O-ring for protection against dirt and foreign particles

Description

Material

Body carbon steel.

Ball:

Form O stainless steel with diamond surface.

Ball:

Form O stainless steel with diamond surface.

Version

Body tempered, black oxidised.

Ball:

Form O surface comparable to 100 grade abrasive grit.

Ball:

Form O surface comparable to 100 grade abrasive grit.

Note

The self-aligning pads are used to support and clamp unmachined and machined workpieces.

In addition, they serve as stops, supports and pressure pieces in fixtures and toolmaking.

Ball secured against rotation.

Form O: The abrasive diamond surface is bonded firmly to the ball. It is ideally suited to supporting smooth or slippery applications with a minimum of clamping pressure. This allows the diamond particles to get a firm grip on a very small area with minimum damage to the surface.

The diamond surface offers excellent wear resistance.

In addition, they serve as stops, supports and pressure pieces in fixtures and toolmaking.

Ball secured against rotation.

Form O: The abrasive diamond surface is bonded firmly to the ball. It is ideally suited to supporting smooth or slippery applications with a minimum of clamping pressure. This allows the diamond particles to get a firm grip on a very small area with minimum damage to the surface.

The diamond surface offers excellent wear resistance.

Advantages

The built-in O-ring holds the ball in place and keeps dirt and foreign particles out, ensuring uniform movement.

The hexagon socket allows easy adjustment and positioning in through holes.

The hexagon socket allows easy adjustment and positioning in through holes.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.