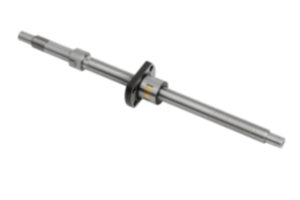

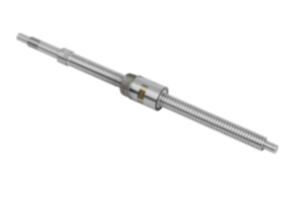

{"product":{"productId":"agid.5031","price":0,"name":"Ball screw linear actuators rolled, with flange nut DIN 69051 Part 5"},"currency":"GBP"}

Material

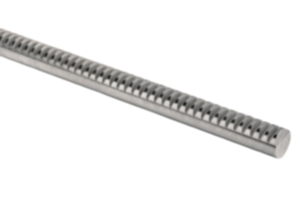

Spindle, steel 1.1213.

Nut steel 1.3505.

Wiper plastic.

Nut steel 1.3505.

Wiper plastic.

Version

Spindle rolled, induction hardened to 62 ±2 HRC and polished.

Nut ground, flank induction hardened to 62 ±2 HRC and polished.

Nut ground, flank induction hardened to 62 ±2 HRC and polished.

Show more

Show less

Description

Material

Spindle, steel 1.1213.

Nut steel 1.3505.

Wiper plastic.

Nut steel 1.3505.

Wiper plastic.

Version

Spindle rolled, induction hardened to 62 ±2 HRC and polished.

Nut ground, flank induction hardened to 62 ±2 HRC and polished.

Nut ground, flank induction hardened to 62 ±2 HRC and polished.

Note

Ball screw linear actuators with 5 mm or 10 mm pitch gothic arch profile threads. Single-start, right-hand. Ball screw-flange nut acc. to DIN 69051 Part 5 with flange.

Manufactured to tolerance class C7 (tolerance ±50 µ / 300 mm). Without preload, with axial play P0 (max. 0.08 mm)

Manufactured to tolerance class C7 (tolerance ±50 µ / 300 mm). Without preload, with axial play P0 (max. 0.08 mm)

Attention

The flange nut must not be removed from the spindle without a mounting aid as the balls will fall out.

On request

We can produce ball screw spindles to your design from a detailed drawing.

Max. production lengths 5600 mm.

Other precision classes and preloading are available (see technical information).

Max. production lengths 5600 mm.

Other precision classes and preloading are available (see technical information).

Drawing reference

1) M6 lubrication hole

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.