Material

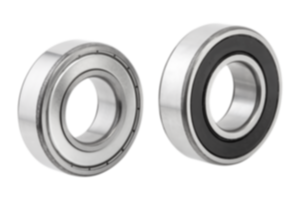

Steel housing.

Nitrile rubber seal.

Nitrile rubber seal.

Version

Ground edges.

Show more

Show less

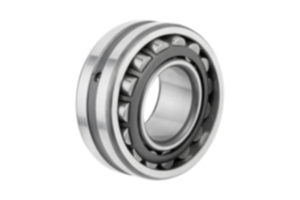

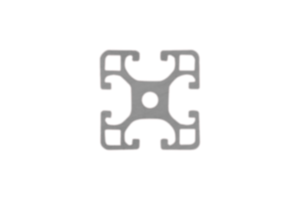

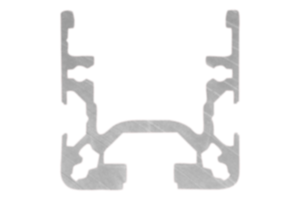

Axial angular contact ball bearing, steel, double row with flange, Form A

from

£174.85

plus sales tax

plus shipping costs

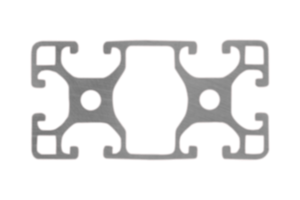

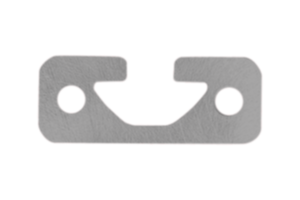

Axial angular contact ball bearing, steel, double row with flange, Form B

from

£186.05

plus sales tax

plus shipping costs

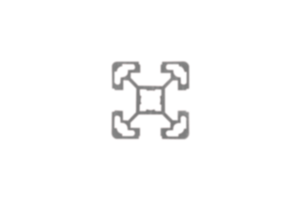

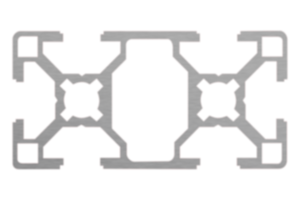

Axial angular contact ball bearing steel, double row with flange, Form C

from

£196.85

plus sales tax

plus shipping costs

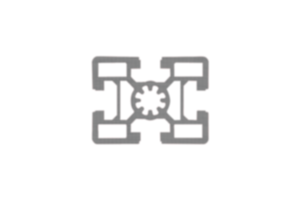

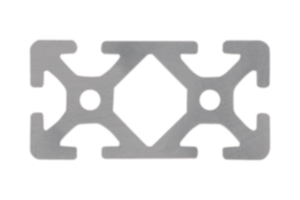

Axial angular contact ball bearing steel, double row with flange, Form D

from

£233.61

plus sales tax

plus shipping costs

Description

Material

Steel housing.

Nitrile rubber seal.

Nitrile rubber seal.

Version

Ground edges.

Note

Preloaded high-accuracy bearings with a 60° thrust angle. The bearings accept both radial and axial forces from both directions. Due to their preload, the angular contact ball bearings provide a high level of stiffness, excellent concentricity, precise tool positioning and repeatability.

The integrated low-friction seal effectively keeps dirt away from the bearing, thereby ensuring excellent operating safety and a long service life.

The bearing friction coefficient Mrl is a reference value.

The moment of inertia corresponds to that of the rotating inner ring.

The limiting speeds are applicable after grease is applied.

The integrated low-friction seal effectively keeps dirt away from the bearing, thereby ensuring excellent operating safety and a long service life.

The bearing friction coefficient Mrl is a reference value.

The moment of inertia corresponds to that of the rotating inner ring.

The limiting speeds are applicable after grease is applied.

Technical Data

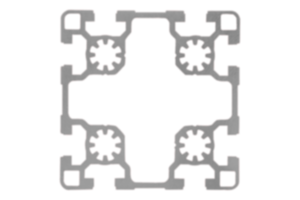

All bearings are supplied ready for mounting with lubricating grease type KE2P-35 acc. to DIN 51825.

Housing and shaft tolerances correspond to roundness tolerance class IT2 and perpendicularity tolerance class IT4.

Housing and shaft tolerances correspond to roundness tolerance class IT2 and perpendicularity tolerance class IT4.

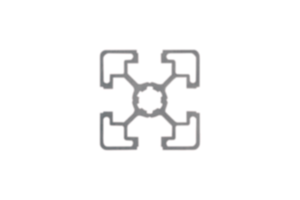

Application

For thread drive bearing.

Temperature range

-30 °C to +120 °C.

Assembly

Precision slotted nuts must be used for mounting the threaded spindles.

To compensate for any material settling during assembly, tighten the slotted nuts using 2x tightening torque, loosen slightly and then tighten using the prescribed tightening torque.

Tighten fastening screws crosswise up to max. 70% of the yield point.

To compensate for any material settling during assembly, tighten the slotted nuts using 2x tightening torque, loosen slightly and then tighten using the prescribed tightening torque.

Tighten fastening screws crosswise up to max. 70% of the yield point.