Material

Elastomer spider, polyurethane Shore 98A.

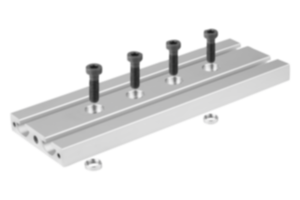

Intermediate tube and clamping hub, aluminium.

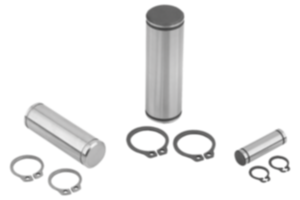

Expanding mandrel steel.

Screws steel.

Intermediate tube and clamping hub, aluminium.

Expanding mandrel steel.

Screws steel.

Version

Bright.

Show more

Show less

Description

Material

Elastomer spider, polyurethane Shore 98A.

Intermediate tube and clamping hub, aluminium.

Expanding mandrel steel.

Screws steel.

Intermediate tube and clamping hub, aluminium.

Expanding mandrel steel.

Screws steel.

Version

Bright.

Note

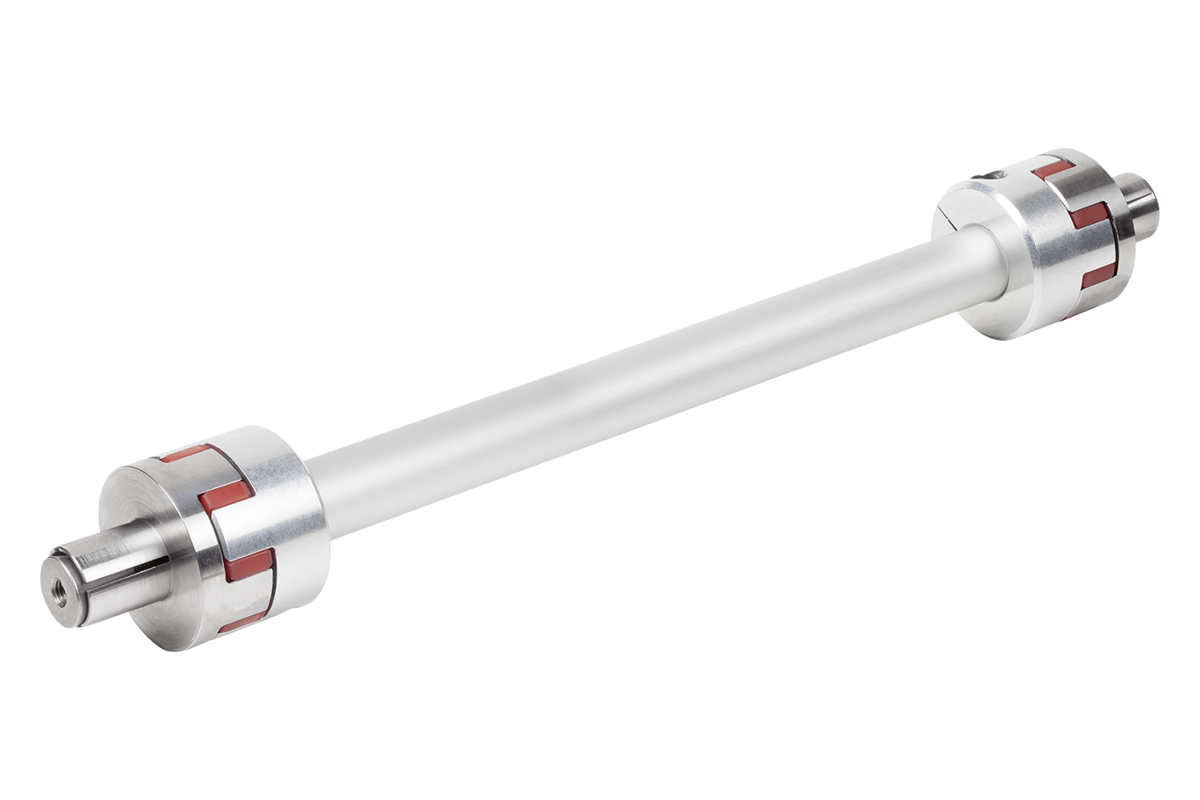

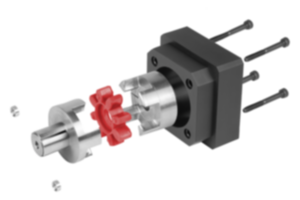

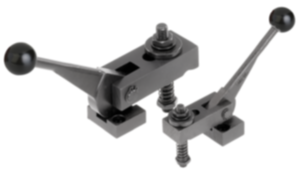

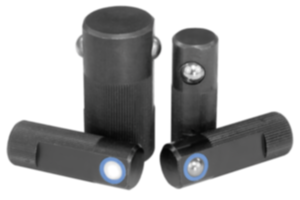

The synchronisation set enables two parallel linear axles to be operated with just one motor.

Synchronisation sets consist of two couplings, which are connected with a synchronous shaft. They are produced to the appropriate length. Suitable for lengths up to max. 3000 mm.

Advantages of the elastomer dog coupling:

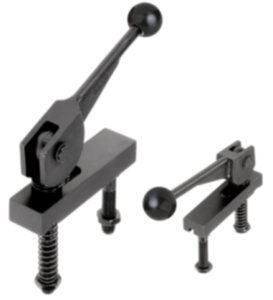

- Hub with expanding mandrel, can be mounted axially

- Play-free with vibration absorption

- Excellent retaining force

- Excellent concentric accuracy

- Short design

- Easy to assemble

- Can be mounted axially on spigot side

- Electrical insulation

- Nominal torque up to 53 Nm

Synchronisation sets consist of two couplings, which are connected with a synchronous shaft. They are produced to the appropriate length. Suitable for lengths up to max. 3000 mm.

Advantages of the elastomer dog coupling:

- Hub with expanding mandrel, can be mounted axially

- Play-free with vibration absorption

- Excellent retaining force

- Excellent concentric accuracy

- Short design

- Easy to assemble

- Can be mounted axially on spigot side

- Electrical insulation

- Nominal torque up to 53 Nm

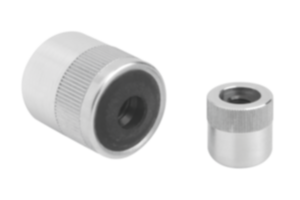

Assembly

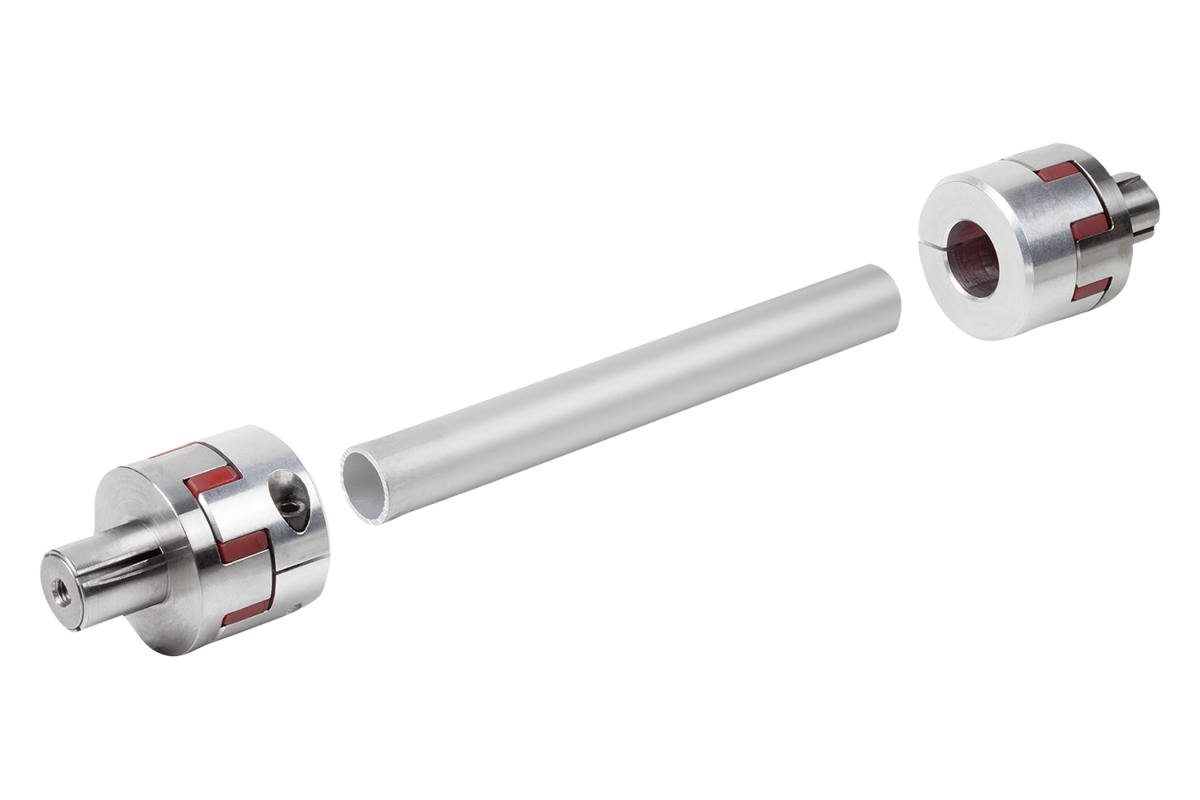

An axial displacement of the attachment parts is not required as the intermediate tube can be inserted as a spacer between the coupling halves.

Both coupling halves with expanding mandrel are fully inserted into the hub bores of the linear units. The frictional connection is achieved by tightening the screws in the expanding mandrel to the specified torque. Push the coupling halves, together with the clamping hub and elastomer spider, onto the intermediate tube. Bring the intermediate tube into position and connect the coupling halves by manually applying a low level of axial force. Tighten the screws on both clamping hubs to the specified torque.

Both coupling halves with expanding mandrel are fully inserted into the hub bores of the linear units. The frictional connection is achieved by tightening the screws in the expanding mandrel to the specified torque. Push the coupling halves, together with the clamping hub and elastomer spider, onto the intermediate tube. Bring the intermediate tube into position and connect the coupling halves by manually applying a low level of axial force. Tighten the screws on both clamping hubs to the specified torque.

Drawing reference

X = distance between shafts

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.