Clamp straps

Clamp straps from norelem - Precise workpiece clamping for optimum machining results

What are clamp straps?

Clamping elements from norelem - Versatility for diverse applications

Durability and reliability of the clamping elements for long-term use

Why buy clamp straps from norelem?

Clamp straps from norelem - Precise workpiece clamping for optimum machining results

Clamp straps play a decisive role in industrial manufacturing. These standard parts are used to securely and reliably clamp workpieces during the machining process. In metalworking, clamp straps are therefore used in a variety of applications. They are used to clamp workpieces on machine tools such as milling machines, horizontal and vertical boring machines and drilling machines. The clamp straps are also used on assembly fixtures and testing equipment. The variety of clamping elements ranges from mechanical clamping devices to complex hydraulic or pneumatic clamping systems. norelem offers clamp straps in various sizes and shapes to meet the diverse requirements. Clamp straps are available made from aluminium and Q&T steel.

Hereyou can see the applications for the clamp strap (04010).

Clamp straps belong to the clamping element group. This forms a fundamental basis in numerous industrial machining processes. Clamping elements are essentially used to hold workpieces during various machining processes. Their areas of application range from metalworking and plastics processing to woodworking. Every norelem clamping element is designed to meet the specific requirements of the various applications and to ensure the best possible clamping for the workpieces.

What are clamp straps?

Clamp straps are standard parts that are used primarily in metalworking. They are used to securely hold workpieces in place during the machining process.

The standard parts are typically made of robust materials such as Q&T steel or aluminium and have a screw that applies the pressure to hold the workpiece securely in place. This screw can be a T-bolt, a hex-head bolt or part of a complete clamp strap assembly.

Clamp straps often also offer the possibility of adjusting the clamping width or height in order to secure workpieces of different sizes. To ensure a firm hold, the clamp straps are often used in combination with other clamping devices such as vices, claw clamps or clamping blocks.

Swivel-heel clamp straps

When a series of workpieces that are too large for a machine vice have to be clamped onto a machine table, the swivel-heel clamp straps can be used. They are designed to be adjusted to suit every workpiece. As with all clamp straps, it is important to ensure that the strap is always parallel to the table surface. The swivel action of this clamp enables large and bulky workpieces to be easily mounted or removed.

Watch an application video of swivel-heel clamp straps

Tapped-heel clamp strap

The tapped-heel clamp straps are a cost-effective alternative to more expensive clamping devices. A screw through the heel of the strap is used to quickly clamp or release the workpiece. A pivot bolt is placed through the slot in the strap, with a spring underneath to hold the strap clear when loosened. Here is an application video for the tapped-heel clamp strap

Clamp straps with flattened ball

The flattened ball in the nose of this clamp strap enables workpieces with inclined or uneven surfaces to be clamped. The ball automatically adapts to a surface inclination up to 9°, so that it is not damaged. This type of clamp strap is particularly suitable for workpieces made of sensitive materials. The strap itself is made of Q&T steel, the ball is made of ball-bearing steel.

In addition to gentle clamping, the ball helps to distribute pressure evenly. The uniform pressure distribution improves stability and safety while machining the workpiece.

Stepped-heel clamp straps

Stepped-heel clamp straps from norelem are available made from steel or aluminium. Stepped-heel clamp straps should only be used together with step blocks. The steps in the step blocks match the steps on the heel of the strap perfectly. The step block gives the clamp strap perfect support and aids in positioning.

We have made an application video to give you an idea of how the stepped-heeled clamp strap and the step blocks work together.

Steel gooseneck clamp straps

This clamp strap is characterised by its offset form. This gives more free space around the workpiece. This type of clamp leads to more clamping flexibility. The workpiece can be clamped so that access to certain areas is improved and collision risks decreased. Our videos show how the pressure can be applied and released, and shows how the clamp straps can be moved backwards and forwards.

The range includes many other types of clamp strap in addition to the small selection mentioned here. Each of the 27 clamps has its own advantages and areas of application.

Clamping elements from norelem - Versatility for diverse applications

In addition clamp straps, there are also the following clamping devices in this product catagory:

- Riser blocks

- Double-sided clamp straps

- Clamp springs

- Hinge heel clamp straps

- Claw clamps

- Clamp strap heel supports

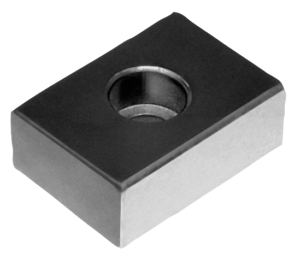

Riser blocks

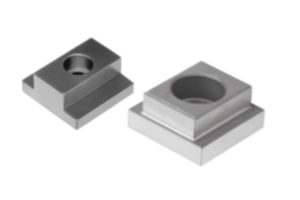

A riser block is used in metalworking and other industrial applications to change the height of workpieces or tools. A riser block is a solid block or plate with precise dimensions. Riser blocks are available in different heights. The main function of a riser block is to precisely set the height of a workpiece or tool above the work surface. They serve as a support surface for workpieces to protect them from damage or contamination. They also provide a stable base during machining.

The riser block Form P is only used in conjunction with clamp straps for clamping. They are made from Q&T steel and are available in various sizes.

Double-sided clamp straps

The main function of a double-sided clamp strap is to hold workpieces securely in place during machining. Two workpieces can be clamped simultaneously using a double-sided clamp strap. As those in the product group are mini double-sided clamp straps, they are only available in the sizes 10 mm, 15 mm and 25 mm high and 16 mm, 24 mm and 36 mm long. they are made from steel and are black oxidised.

Clamp springs

Clamp springs are used to support the clamp straps. They are placed under the strap and locked in place with a wing screw. The clamp spring is available in three sizes. By all sizes the thrust and retaining ring is made from Q&T steel and the spring is made from spring steel. The thrust and retaining ring is black oxidised, the spring is left bright.

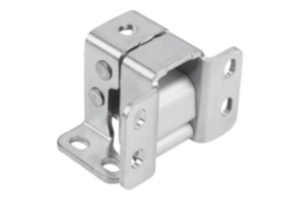

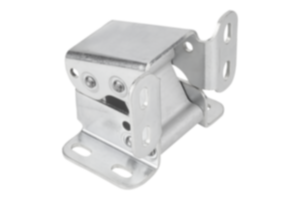

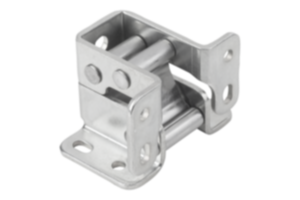

Hinged heel clamp strap

A hinged heel clamp strap is a hinged mechanism which quickly clamps or releases the workpiece. The main function of this type of clamp strap is to securely clamp a workpiece being machined on a machine tool or worktable. The strap is rotated over the hinge onto the workpiece and secured by a bolt through the open slot at the other end.

A bevel faced hex nut should be used to tighten the hinged heel clamp strap.

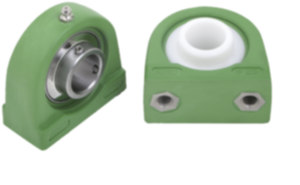

Clamp strap units

Clamp strap units are assemblies for clamping workpieces. They consist of a robust metal construction and can have various strap types that hold the workpiece in place.

The "clamp strap" product family has two types of clamp strap unit:

- Pivot clamp strap units: The clamping force of the pivot clamps is applied from above. They are designed for high loads and are suitable for clamping on shearing and punching tools. Clamping at different heights is possible with this type. Pivot clamp strap units require little space on machine tables. These are available in two versions: Form A is the strap only, Form B is the complete assembly with pivot strap, T-slot bolt, nut and washer. Here is a YouTube applications video.

- Clamp strap unit with pin-end strap: The pin-end strap supplied with this clamp strap unit enables an even distribution of pressure on the workpiece, resulting in improved stability. This minimises damage or deformation of the workpiece, especially with sensitive materials or surfaces. The clamp strap unit with pin-end strap is made from Q&T steel. Other clamp straps can be used on this assembly.

Adjustable heel supports

Heel supports are accessories for the clamp straps assemblies. They support the heel of the strap and consist of a thrust pad, support bolt and fastening screws for the clamp strap.

The heel supports in this group are only for use with the clamp strap assemblies. They are fastened to the rocker pads of these assemblies and can be used to increase the height of the entire unit.

Durability and reliability of the clamping elements for long-term use

Clamp straps offer a number of advantages in metalworking and other industrial applications. Some of these are:

- Safety: Clamp straps help to hold workpieces securely and firmly in place. This reduces the risk of accidents and injuries. Through secure clamping, machine operators can work more safely.

- Precision: Clamp straps enable workpieces to be accurately positioned and clamped, which leads to precise machining results. This is especially important by the manufacture of parts with high tolerances and complex geometries.

- Efficiency: Machining processes can be organised more efficiently through the use of clamp straps. Workpieces can be quickly and easily clamped, reducing setup times and Increasing production output.

- Versatility: Clamp straps are available in various sizes, shapes and configurations. The range comprises 27 clamp straps, able to meet the requirements of different applications. The clamping elements can be used on a variety of machine tools and workstations.

- Economic efficiency: Thanks to precise and secure clamping, workpieces can be machined accurately. Accurate machining reduces rejects and post-processing, which in turn improves the overall cost-effectiveness of production processes.

Why buy clamp straps from norelem?

When it comes to safety and precision in metalworking, choosing the correct clamp strap is crucial. For this reason, many professionals and companies choose to buy clamp straps from norelem. Because norelem stands for quality and reliability in industry and is known as a supplier of high-quality products for mechanical processing. These clamping elements are available in a variety of sizes, shapes and materials to meet your requirements.

You have questions about our clamping elements? We are here to help you with any questions or problems you may have.