norelem gas springs

When bodies need to be controlled, braked or moved without great force, then gas springs are often used in construction technology.

norelem gas springs are usually used for damping the movements (opening, closing, adjustment) of hatches, caps or hoods. Due to their high corrosion resistance and low maintenance requirement, gas springs are a very convenient solution for designers working in machine construction. Gas springs are frequently used in the following areas:

- Machine construction

- Fixture construction

- Plant construction

- Furniture industry

- Sports and leisure equipment

- Household appliances

- Automotive industry

- Food industry (stainless steel version)

norelem gas springs are filled with nitrogen and oil. In the stainless steel version, the oil complies with FDA regulation 21 CFR 178.3570 on ‟Lubricants with incidental food contact”. These stainless steel gas springs can therefore be used in the food processing industry. Gas springs can withstand working temperatures from -20° to +80° Celsius. On customer request, norelem can adjust the gas pressure in the gas springs to the individual requirement. Customers can therefore order a ready-to-install end product from norelem via the catalogue or the webshop. The gas spring extension forces can also be reduced afterwards using the integrated filling valve. Depending on the version, the piston rod in the gas springs can be made either of steel or stainless steel (1.4305). The piston rod diameter varies between 6 and 14 mm. The piston stroke is between 40 and 400 mm. norelem gas springs have a connecting thread on both sides. This means that connecting parts can be easily joined on both sides of the spring. Since June 2018, norelem has also been offering a comprehensive range of gas springs in stainless steel. Stainless steel springs can be used universally.

norelem adjustable shock absorbers

norelem industrial shock absorbers absorb the energy from moving (accelerating) bodies and convert kinetic energy into heat through friction with the internal oil flow. Shock absorbers therefore work by the basic physical principle of energy conservation. The thermal energy generated in this way is transferred to the cylinder body of the shock absorber, from where it passes out into the environment. Industrial shock absorbers brake moving bodies quickly and gently. They are therefore suitable for use in handling devices, turn & swivel units, linear cylinders, and many other industrial applications, especially automation.

Shock absorbers from norelem are available in steel or stainless steel. They are ready to install and maintenance-free. All types have an integrated end stop. Shock absorbers are generally always available as configurable variants through the webshop or the catalogue. Their special feature is their flexibility, with an adjusting screw on the base which allows the shock absorber to be adapted perfectly, for example if there are changes in the operating conditions. The stainless steel range of shock absorbers are filled with an edible oil which meets the approval requirements (USDA-H1) of the food industry. This series is made from 1.4404 steel (casing) or 1.4125 steel (piston rod). They are suitable for a temperature range from -50°C to +120°C. All shock absorbers have an integrated end stop. The end stop can also be adjusted and fine-tuned individually using the stop nut.

norelem rubber buffers

Rubber buffers (also known as rubber-metal buffers, silent blocks or anti-vibration buffers) consist of a combination of natural rubber (elastomer) and a metal component such as steel or stainless steel. Rubber buffers are mostly used in machine construction as vibration dampers or as stop buffers as they are inexpensive and easy-to-install standard products. Rubber buffers absorb kinetic energy and so reduce (dampen) the pressure, thrust and vibration in the whole system. Rubber buffers are therefore often used to cushion shocks or recurring movements and as end stops. A rubber buffer significantly reduces the vibration amplitude. Use as a ‟door stopper”, ‟door buffer” or as a machine foot is a classic application of rubber buffers in practice. In addition to various thread lengths, norelem has many different types and versions of buffers in its range.

Note: Rubber hardness: hard = 70° Shore, medium = 55° Shore, soft = 45° Shore. Temperature range: -30°C to +80°C. norelem rubber-metal buffers are RoHS-compliant.

norelem compression springs

Compression springs to ISO 10243 are heat-treated to ensure the longest possible service life in use. These compression springs support a large range of changing and continuous loads. They can be used in operating temperatures up to 230°C. Classic areas of application can be found in the automotive industry and in process engineering. norelem has four different basic versions of compression spring made of chrome-silicon steel in its portfolio:

- A green version for light loads

- A blue version for medium loads

- A red version for heavy loads

- A yellow version for very heavy loads

The exact specifications can be found in the data sheet on the detailed product page.

norelem elastomer buffers

Elastomer buffers are often used in practice to attenuate air or structure borne noise. These buffers are very hard-wearing and resistant to oils and grease. In general, norelem elastomer buffers are available in three different Shore hardnesses: Shore 70A (black) / Shore 80A (yellow) / Shore 90A (red).

Elastomer buffers are inexpensive, maintenance-free and have a long service life. All norelem buffers are RoHS compliant.

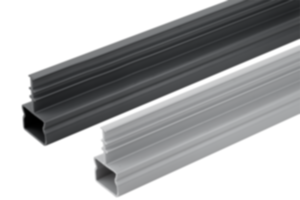

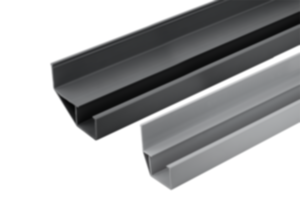

norelem profile dampers

Profile dampers are inexpensive and maintenance-free buffer elements used as end position dampers or end stops in machine tools, linear axes, pneumatic systems and handling devices. norelem profile dampers are suitable either for continuous use or as emergency stops.

In general, there are two different versions of the dampers: radial (soft and hard) and axial (soft and hard). norelem sells its profile dampers ready for installation with a special fastening screw. Energy absorption is between 58% and 73%. At a maximum impact speed of 5 m/s, a dynamic force from 870 to 35190 Newton can be absorbed. These profile dampers are resistant to seawater, chemicals, and microbes. Their material does not absorb water. This means that the co-polyester elastomer does not swell. The material hardness is Shore 55D.