norelem drill bushes

Drill bushes enable quick drilling of workpieces without having to repeatedly measure and mark the drilling points in advance. The practical helpers, which guide the drill directly into the drilling jig, not only guarantee a perfect drilling pattern, but also ensure that the drill cannot stray.

In contrast to drilling without a jig – hand-guided drilling – the drilling process is significantly simplified thanks to the drill bush and achieves a much cleaner result by maintaining a fixed penetration angle.

All drill bushes are also made of special case-hardening steel, which means they fulfil high quality standards and are also particularly durable.

Advantages of norelem drill bushes at a glance:

- Fast drilling possible

- Perfect drilling pattern

- Exact configuration

- Common standardised parts system

- Drill does not stray

- Simplification of the drilling process

- Clean drilling result

- Use of special case-hardening steel, therefore high quality and durability

Areas of application for norelem drill bushes

Drill bushes are primarily used for deep drilling in machine construction. norelem drill bushes are also used daily in the manufacture of tools in vehicle construction as well as in various other branches of industry such as trades. norelem drill bushes are designed for harsh environments and a long service life.

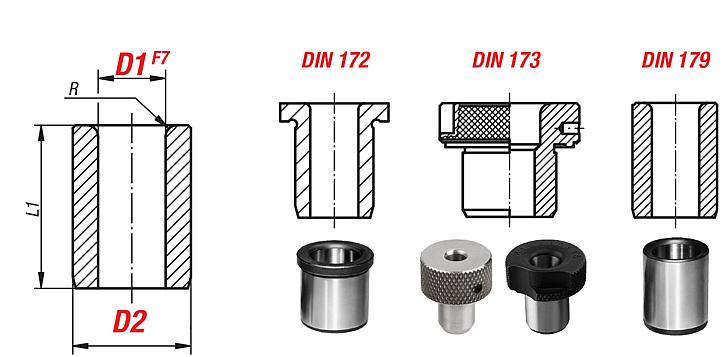

Versions, forms and standards

norelem supplies drill bushes for a wide range of requirements – precision tools tailored to your specifications. Whether as cylindrical drill bushes, with flanged drill bushes, as push-in drill bush, drill bush clamps or flat-head shoulder screws for push-in drill bushes – an exact configuration according to requirements is possible thanks to suitable dimensions and a variety of forms.

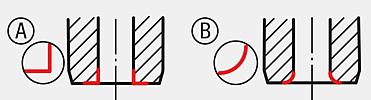

According to the type, the drill bushes conform to the current standards (DIN 172, DIN 173, DIN 179 and ISO 4247) and are available in Form A (bore rounded one end) and Form B (bore rounded both ends).

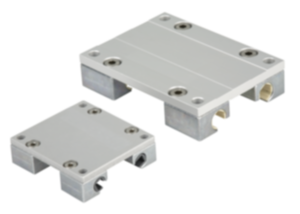

DIN 172 – Flanged drill bushes

The flange on flanged drill bushes ensures that the drill bush cannot be “pressed through” downwards during use. For this reason, the flange of the DIN 172 drill bush protrudes slightly.

- Form A: The bore is rounded at one end

- Form B: The bore is rounded at both ends

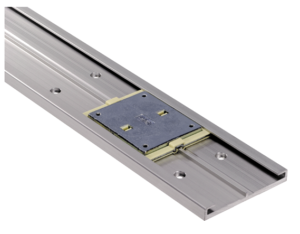

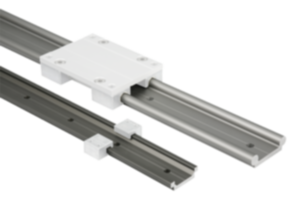

DIN 173 – Push-in drill bush

Push-in drill bushes have the advantage over cylindrical drill bushes that the bush can be replaced quickly. This means that different diameters can be realised in a shorter time. Together with DIN 173 drill bush clamps, DIN 912 socket head screws and DIN 173 flat-head shoulder screws, the push-in drill bush produces a reliable and clean result.

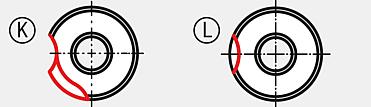

- Form A: There is no insertion groove here – This drill bush is mainly used for drilling holes with the aid of drilling jigs as it enables quick changeover for different drill diameters.

- Form K: This is used as a quick-change bush for right-cutting tools.

- Form L: This is a so-called interchangeable bush.

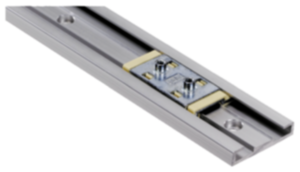

DIN 173 – Drill bush clamps

The drill bush clamp is used in practice to secure the push-in drill bush. The drill bush clamp secures the push-in drill bush and thus ensure safety when using the machine.

Note: The 1.0711 drill bush clamps are supplied with a steel DIN 912 socket head screw, thus eliminating the need to purchase such a socket head screw separately for the drill bush clamp to function properly.

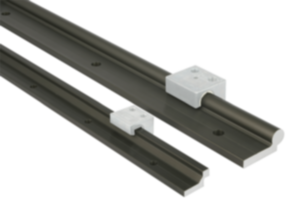

DIN 179 – Cylindrical drill bushes

Drill bushes according to DIN 179 are so-called cylindrical drill bushes. They are made from special case-hardening steel and are hardened and ground.

Cylindrical drill bushes are also frequently used as positioning bushes. The bush can be pressed in flush. The drill bushes to DIN 179 can be combined with so-called push-in drill bushes to DIN 173.

- Form A: The bore is rounded at one end

- Form B: The bore is rounded at both ends

DIN 173 – Flat-head shoulder screws for push-in drill bushes

The flat-head shoulder screws made of bright steel are designed for DIN 173 push-in drill bushes with a diameter of up to 6 mm and from 6 to 30 mm. Do you need flat-head shoulder screws made of bright steel? Then these screws from norelem are sure to fulfil your requirements.

Our products are available in strength class 10.9. Our flat-head shoulder screws are also available in different sizes: from M5 to M8 – meaning that you’re ideally equipped for all possible flat-head shoulder screw installations and for clamping drill bushes. This because the flat-head shoulder screws can only clamp your drill bushes easily and without annoying protruding edges if they are the right size.

Drill bush data sheets

An overview of all data sheets for norelem drill bushes is given below:

- Data sheet 08900 Cylindrical drill bushes DIN 179

- Data sheet 08910 Flanged drill bushes DIN 172

- Data sheet 08926 Drill bush clamps DIN 173 Part 1

- Data sheet 08920 Push-in drill bushes DIN 173

- Data sheet 08920 Push-in drill bushes DIN 173 Part 1

- Data sheet 08927 Flat-head shoulder screws for push-in drill bushes DIN 173