Cam levers from norelem

A cam lever is a mechanical component that is used in various applications. The lever can be used to clamp workpieces quickly and torque-free. The lever allows fastening and adjustment operations to be carried out with the same level of safety.

What is a cam lever?

Application areas of a cam lever

Operating principle of a cam lever

Advantages of using cam levers

Cam levers from norelem

Various versions of cam levers

The norelem range

What is a cam lever?

A cam lever is a flexible standard part that enables torque-free clamping. The lever is inserted through a thread. The cam clamp allows the tension to be quickly built up and released again. Shortly before reaching the clamping point, the cam lever has a good clamping/lever force ratio and has a self-locking effect.

The lever is made up of several components that together determine its function.

The most important components of a cam lever are:

- The grip lever

- The thrust washer

- The hinge pin

- And, depending on the thread type, a stud

The lever arm or other structural parts of a cam lever can be made of various materials, including metals such as aluminium, stainless steel and steel or plastics such as polyamide.

Application areas of a cam lever

Cam levers are a crucial element in the world of mechanics and machine construction due to their versatility and efficiency. They are used in a wide range of applications, including machine construction, the automobile industry and many other sectors. The cam lever is used wherever components need to be tensioned, clamped or fastened to machines, fixtures or devices.

The operating principle is simple. The lever is attached to the component via the hinge pin. When the grip lever is actuated, the thrust washer tightens and fastens the part. The specific use of cam levers can vary depending on the application. This makes them extremely versatile and useful in many mechanical systems.

Operating principle of a cam lever

The operating principle of a cam lever is designed to enable components to be fixated quickly and reliably. The basic operating sequence can be described as follows:

In the rest position, the cam tension lever is in a stable state without any tension or force being exerted on the component to be fixated. The cam is set in rotation by actuating the lever. Due to its cam arrangement, the cam starts to perform a circular movement around the centre of rotation. During the clamping process, the rotation of the cam is converted into a linear or reciprocating force. This force is then transferred to the component to be clamped, holding it securely in place.

The cam achieves a particularly efficient ratio between clamping force and lever force just before the clamping point. At this stage, the cam clamp is self-locking, which ensures stable and reliable fixating.

A characteristic feature of the cam tension lever is the ability to individually adjust the clamping position. This is usually made possible by a fine thread, which allows the optimum clamping position to be found for the grip lever.

Thanks to this operating principle, the cam tension lever offers a precise and easy-to-use solution for quick fastening and clamping processes in various areas of application.

Advantages of using cam levers

The use of cam levers offers numerous advantages, including fast and efficient operation, precise clamping force control, self-locking effect and customised clamping positions.

The individual advantage in detail:

- Quick and efficient operation: Cam levers enable quick and efficient operation. Thanks to the cam function, the tension can be released and re-established quickly, which saves time.

- Precise clamping force control: The design allows precise control of the clamping force exerted on the component. This is particularly important in applications that require precise adjustment.

- Versatile areas of application: Cam levers are widely used in various industries, including machine construction, the automobile industry, woodworking, medical technology and more.

- Self-locking effect: Just before reaching the clamping point, cam levers often have a self-locking effect. This ensures stable fixating of the component.

- Customised clamping position: Many cam levers offer adjustment options for the clamping position. The optimum position for the grip lever can be customised using fine threads or other mechanisms.

- Space-saving design: The compact design enables use in applications with limited space.

- Easy handling: As a rule, operation does not require any complex tools or additional aids. A simple screwdriver is often sufficient for adjusting the clamping position.

- Avoiding workpiece damage: Precise control of the clamping force and the self-locking effect minimise the risk of damage to or destruction of the workpiece.

The combination of these advantages makes cam levers an important component in industry.

Cam levers from norelem

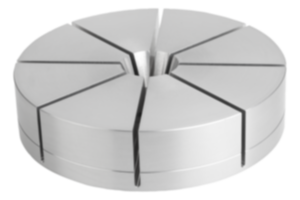

norelem offers a wide range of cam levers in various versions to meet the requirements of different applications.

For example, the selection of thread sizes enables precise customisation to individual requirements. The classic cam levers have a thread size of M6 or M8. However, the available sizes include cam levers from M3 to M10. The product selection can be filtered on the overview page according to the thread sizes.

Various versions of cam levers

In addition to the thread sizes, the levers can also be differentiated by other criteria.

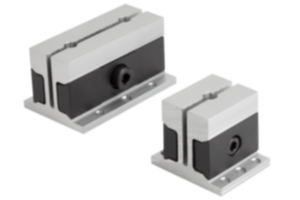

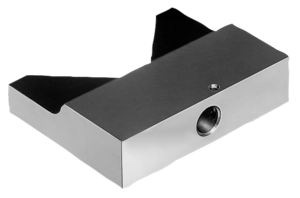

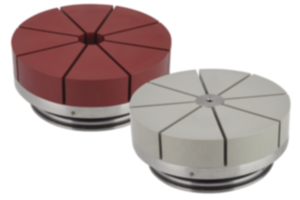

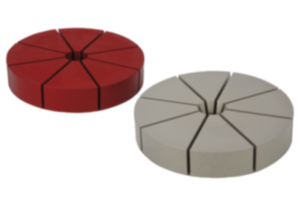

The norelem cam levers are characterised by different versions. In addition to different materials for the base body such as aluminium, stainless steel and polyamide, the lever is also available in steel. The range also includes a variety of colour options, including ruby red RAL 3003, black and traffic red RAL 3020. With different thread types (external or internal thread) and the option of customised adjustment, the cam levers from norelem are extremely adaptable.

Cam levers with internal thread can be mounted on external threads. The lever consists of a grip lever, a thrust washer, a hinge pin and a steel washer. The levers with internal thread are available in thread sizes M3, M4, M5, M6, M8 and M10. The cam lever can be purchased in the colours ruby red, traffic red and black or is available in a steel look.

The cam lever with external thread can be mounted on components with an internal thread. It has the same design as the cam lever with internal thread, but the lever with external thread also has a stud. The lever is available in the colours ruby red, traffic red, black and in a steel look. The thread sizes are M3, M4, M5, M6, M8 and M10.

The norelem range

At norelem, you not only get high-quality cam levers, but also a wide range of benefits. The norelem range is characterised by the highest quality. The quality is reflected in the durability of the products.

In addition, norelem offers outstanding customer service and fast delivery times. The possibility of customisation and the wide range of products make the company the ideal choice for your requirements.

The experienced team is always available to answer your questions and help you choose the right cam lever.